Extruder Service

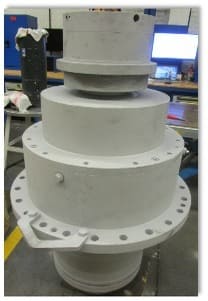

Based on our decades of experience as a manufacturer of drive components for extruders and peripherals, we provide manufacturer-independent service for your single- and twin-screw extruder gearboxes, safety couplings, and machine elements (e.g. V-belt pulleys). Rely on our expertise and comprehensive maintenance services – 24 hours a day, 365 days a year. Our experienced service and system technicians are available around the clock, both domestically and internationally.

On-site service:

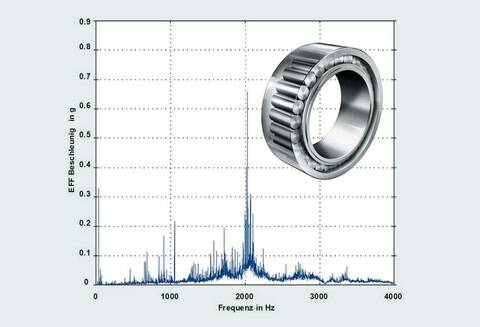

- Condition monitoring (online via particle analysis, endoscopy, vibration analysis, and more)

- Checking timing and axial offset using gauges, measuring arms and/or 3D scans

- Laser optical alignment, belt alignment, and imbalance measurement

- Component replacement and on-site repair (leakages, etc.)

- Re-engineering and modifications to extend service life

Contact us now for a non-binding needs analysis and arrange a consultation with your personal customer support representative.

Typical applications:

- Cooling and hot mixers

- Shredders and kneaders

- Cascade extruders and sheet extrusion

- Regranulation / repolymerisation

- Profile extrusion, main and co-extrusion

- Film blowing and polyfilm stretching systems

- Calenders and laboratory extruders

- Compounding and masterbatch

- Degassing and side feeders (VE process units)

- and more

As a manufacturer, we have an extensive production portfolio, certified suppliers, and a wide-ranging stock of spare parts, ensuring prompt spare parts supply, the necessary special tools, and our own logistics. Professional in-house refurbishment includes analyses according to international standards, adjustment of shafts where required, and final test runs on our test benches with full documentation.