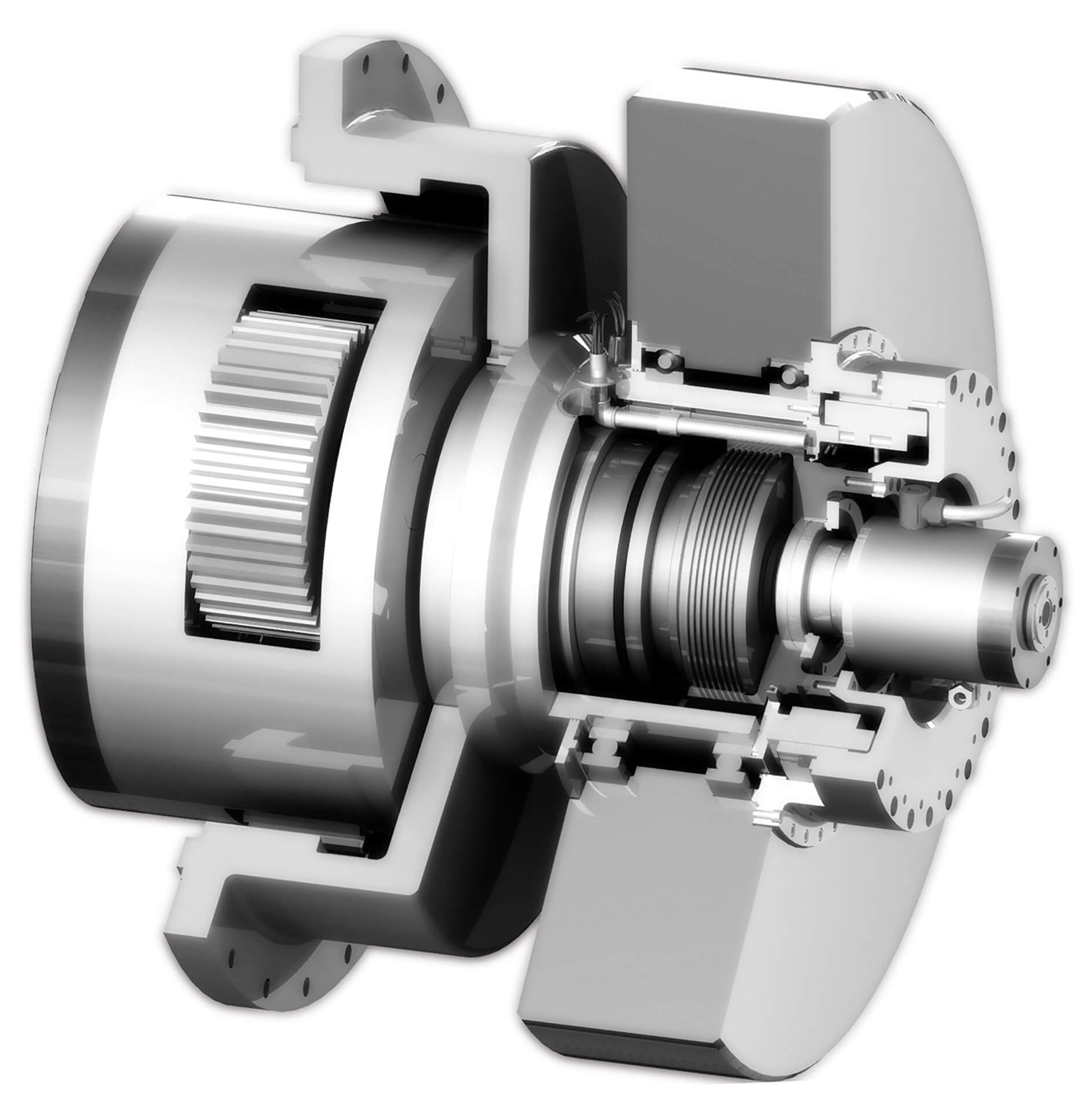

This flywheel direct drive is a further development of the Nidec DESCH standard complete drive, which has already proven itself many times over in numerous applications. A highly efficient torque motor is integrated into the flywheel. It operates almost wear-free and offers the highest power density in the smallest installation space. The advantage for the machine manufacturer is that the previous motor, the motor mount and the complete belt drive are not required. This in turn simplifies the assembly of the press and saves assembly time.

areas of application: Presses

Contact us now- Torque range from 2 kNm to 2500 kNm (depending on available torque motor)

- Gear ratios i = 3.5 – approx. 10 as a single-stage planetary gearbox

- Gear ratios up to i = 100 possible as a two-stage version

- Preferred gear ratios: i = 4 and i = 6

- Punching machines

- Eccentric presses

- Knuckle-joint presses

- Servo presses

- Wear- and maintenance-free drive

- Low noise level

- No belt drive required, enabling more cost-effective machine design

- No need for motor mounting or belt transmission

- Compact and simple design

- Small protective cover

- FEM-supported component optimization

| Complete Press Drive KAE | Download |

|---|